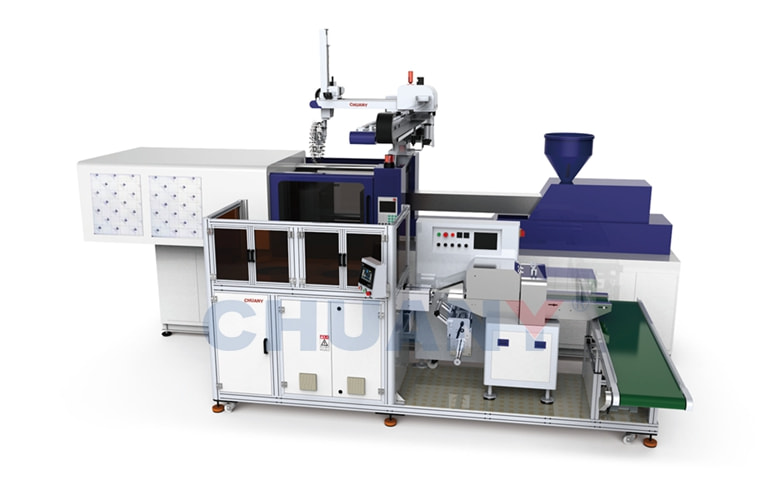

Plastic Cutlery Turnkey Solution

Plastic Cutlery Injection Molding

Large production capacity and lower production cost are the key points to gain the competitive advantage in the industry of disposable plastic spoon fork and knife.

With years of experience and successful project cases, CHUANY has worked with bench-marking industry customers from all over the world, growing up together in the long-term corporation. Based on win-win principle, we provide all customers high quality, high efficiency and cost effective automatic turnkey products.

Application

With its highly developed application expertise, CHUANY builds tooling solutions based on various mold design features and proprietary technologies to ensure maximum productivity through fast cycling, higher cavitation and reliability.

Different size in different material products, for example, PP ford-able fork and spoon for instant food, PS cutlery for party or take-away, PLA cutlery for new green lifestyle, all required massive production capacity with decent quality in shortest cycle time.

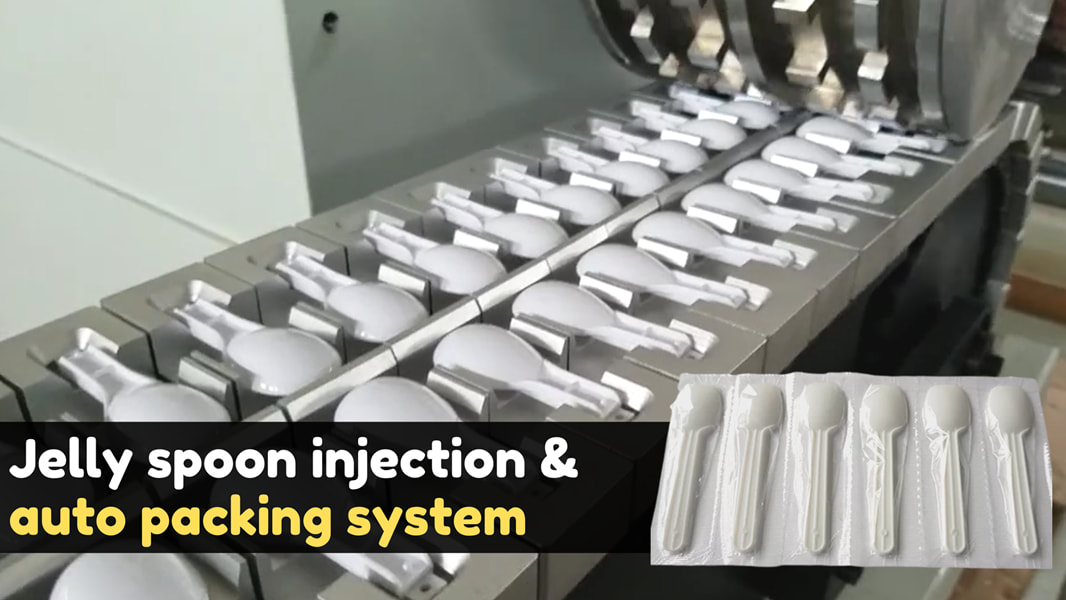

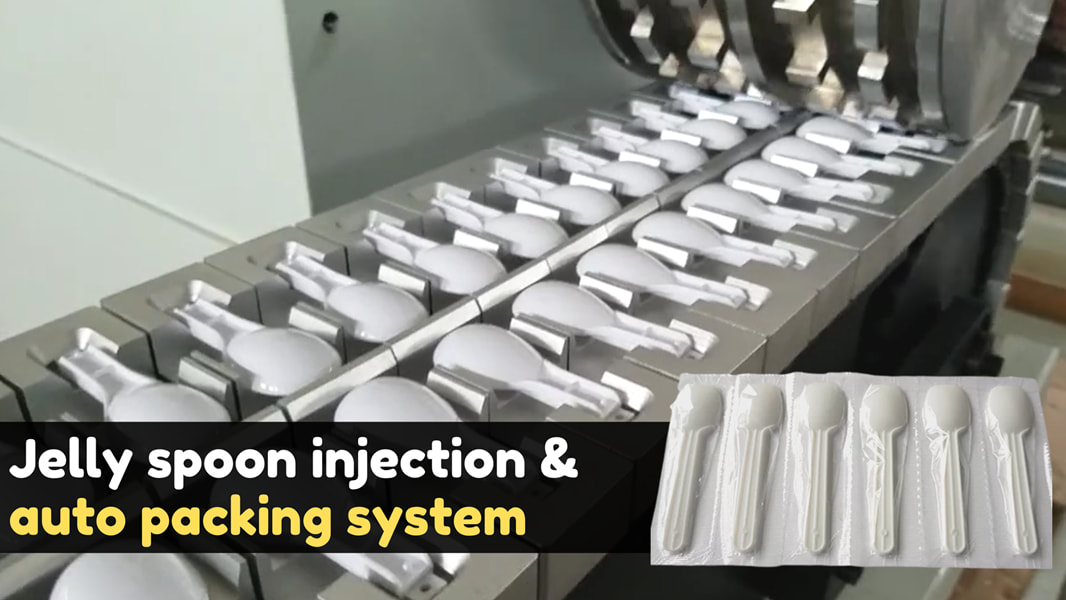

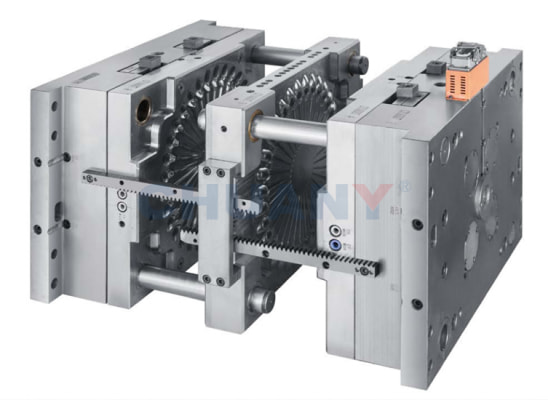

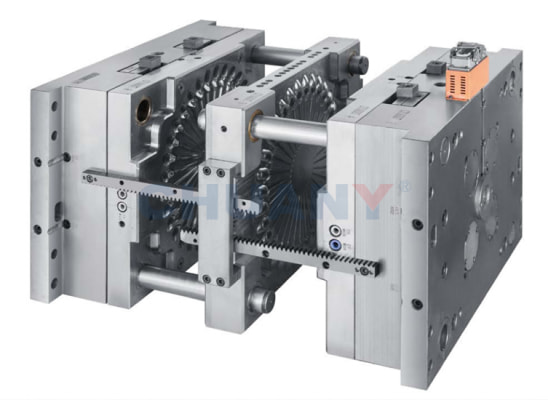

Cutlery Mold

Cutlery Molds, high cavitation system performance can be enhanced by a range of CHUANY’s technologies including stack molds, quick product change features, as well as In Mold Closing.

With hundreds of mold-making cases and high-precision processing equipment, CHUANY team is constantly improving and adjusting their mold designs to be the most efficient and stable mold.

Most of CHUANY’s cutlery molds have been built in two plate mold or stack mold configuration, for such as 32/36/48/64 cavities etc.

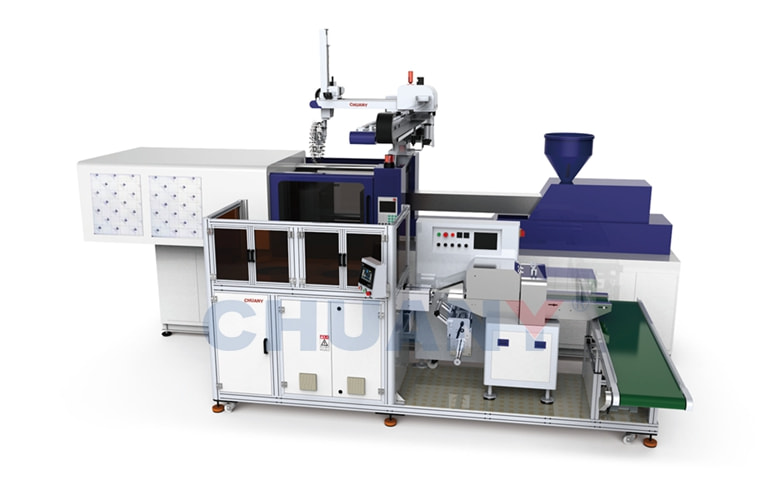

Cutlery Packing System

First automatic plastic cutlery packing system in China. Our key focus is to find solutions which enable our customers to turnkey products and plastic features at commercial outputs with the lowest possible part cost.

Features

- System includes the high-speed pick-out robot, an automatic stacking fixture, a transfer fixture, (product transfer robot), and an automatic packing machine.

- Production process from plastic raw materials to product packaging is fully automatic production, without any human contact and secondary pollution, which is environmentally friendly and high efficient.

- Available for various package way, single wrap, four side seal package, and more pieces bulk pack.

- Film material are applicable packing in OPP, BOPP, CPP. Punching methods of packaging bags are butterfly hole, round hole, not punching optional.

- Save labor cost, increase company competitiveness.