IML Turnkey Solution

IML Container Injection Molding

In fastconsumable times, In Mold Labeling system is widely used in product package, thanks to its good characteristics of perfect surface, waterproof, anti-corrosion, packaging security and protection from counterfeiting.

With the label being the same material as the IML containers, counterfeiting by removing the label and inventory serialized barcode is impossible. Additionally, sustainability is enhanced because the label and container can be recycled together after many years of research and development.

CHUANY team is fully capable of integrally controlling the IML key technology, and flexibly making various IML turnkey solutions, offering the ability to integrate IML mold, machines, automation, and post-mold handling equipment with our tooling solutions to optimize productivity and lower overall part cost.

Application

In-Mold Labeling Container (IML) products have expanded rapidly to new market applications with single dimension, 3-5 sided and wrap-around applications for food, household, medical and cosmetic industries.

- Food packaging (e.g. cups, trays, jars, ice cream, yogurts, prepared meals, butter, sauce)

- Household packaging (e.g. buckets, containers)

- Medical and cosmetic (e.g. tubes, jars, bottles)

Benefits of IML

- Shorter production time and lower Production Costs

- IMLs and closures consist of the same material and can therefore be fully recycled

- Outstanding print quality

- Scratch Proof Surface

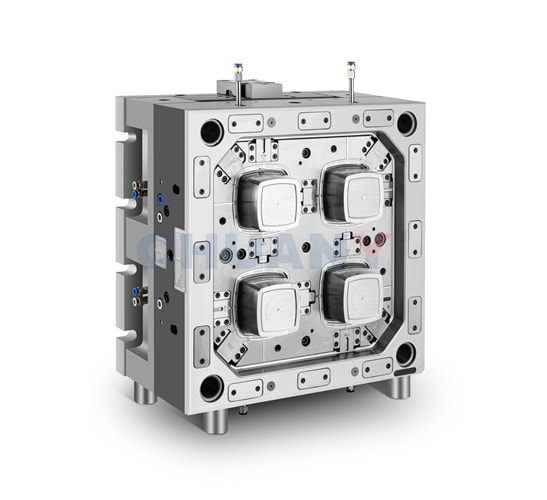

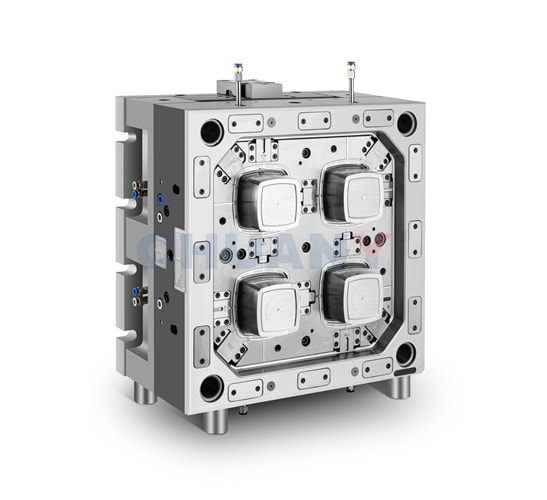

IML Mold

In IML Solutions, CHUANY has a professional team of IML mold engineers to provide customers with perfect mold and product solutions through advanced mold development and analysis software.

IML mold has an optimal structural design to ensure high repeatability and less deformation after a long period of use. Meanwhile, the excellent cooling performance ensures high productivity and good quality of finished products.

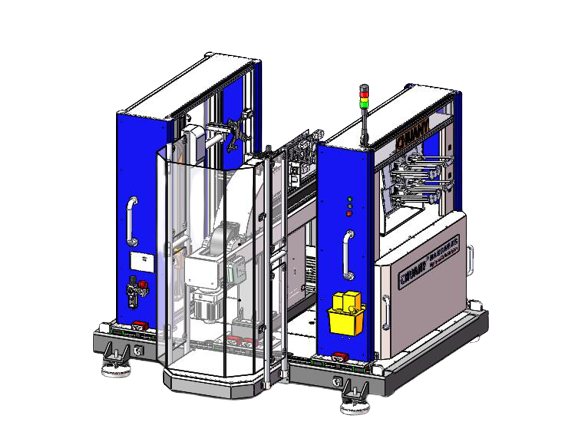

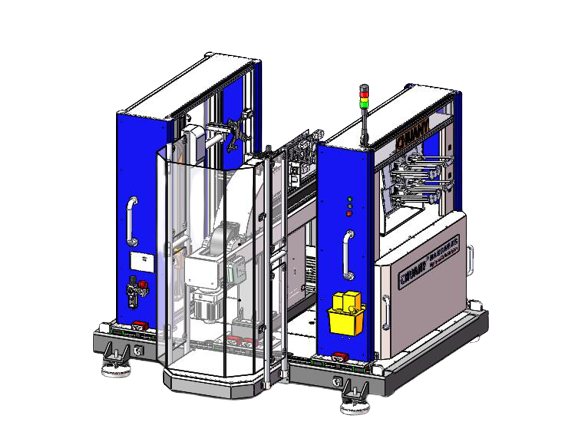

IML ROBOT SYSTEM

Vital point for an efficient and successful IML production process is precise label placement into the IML mold cavity by the IML robot during each and every cycle with a stable electrostatic system.

CHUANY ’S ROBOTS ARE:

- Ultra-precise

- Robust, built with the highest quality components

- Flexible

- Universal

- Versatile

What we have

SIDE ENTRY IML SYSTEM

Side entry IML robot ensures specific advantage throughout the short cycle time and precision production, and offers remarkable productivity potential for customers.

TOP ENTRY IML SYSTEM

Top entry robots for IML concerns small production with a flexibility, suitable for the big product with long cycle time.